Three models debut this coming fall—exclusive to REI

When Black Diamond’s climbing category manager Kolin Powick stopped by our offices in Boulder, Colorado, to give us a sneak peek at the company’s new rock shoe line, we had one big question: “Why shoes?”

“You’re not alone,” he laughed. “That’s the number one thing people ask us. But it’s been in the works for years. What we’re saying at BD is ‘Finally!'”

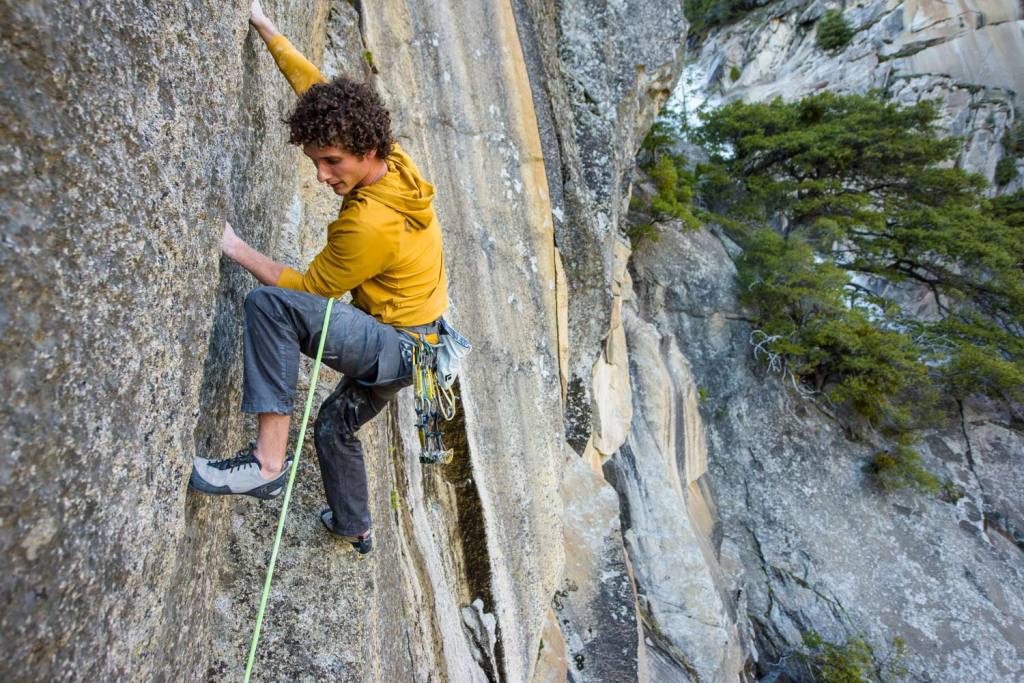

On lead in the Aspect | Photo: Courtesy Black Diamond

It’s easy to forget that back in the day, Black Diamond, or “BD,” was the North American distributor for Scarpa. During that time, Powick says, staffers developed an eye for craftsmanship and as core users, also grew to have input into new rock shoe and mountain boot designs. But when that relationship ended in 2005, BD chose to pursue developing a line of ski boots.

“Looking back, knowing what we do now about the boom in rock climbing and the outrageous growth in climbing gyms, that was perhaps a left turn,” Powick said. “Not to mention ski boot molds can cost seven figures apiece.”

“Truth is, we’ve been wishing for rock shoes for a long time, and our staff DNA is such that we design stuff we want to use. This [rock shoe] project has been underground for years,” he said. “And, when you think about it, isn’t it kind of odd that up until just now, two of the most essential items you need for rock climbing—shoes and ropes—were two things Black Diamond didn’t make?”

Touché. Why not shoes?

Bouldering in the Momentum | Photo: Courtesy Black Diamond

This coming fall, BD will launch the Momentum, an all-purpose VELCRO rig in men’s and women’s ($89) and kids ($59), and the Aspect ($139), a German leather lace-up trad shoe with a low-profile toe that looks great for Indian Creek splitters. These models will be sold exclusively at REI beginning in October 2017. Then two high-performance shoes–the Focus ($174) and the Shadow ($180)–will debut in early 2018 to round out the line.

BD will feature three formulas of rubber across the line. They are using NeoFriction (a proprietary rubber from Korean climbing shoe company Butora) as a baseline rubber on the Momentums, NeoFriction Force as a harder rubber used on the Aspect and Focus for precise edging, and NeoFriction Fuse as a softer rubber used on the Shadow for grip on severely overhanging terrain. The shoes are manufactured in China at Butora’s factory.

“The folks behind Butora are technical wizards and live to climb,” Powick said. “They’re a perfect partner and located right in the heart of real shoe manufacturing innovation.”

Left to right, The Aspect, Kids’ Momentum, Men’s Momentum, and Women’s Momentum | Photo: Shannon Davis

There are a handful of things that make Black Diamond’s approach to shoes notably unique:

Their use of a polyester-propylene knit. The Momentum’s attention-grabbing upper looks reminiscent of some running shoes. “We can program the machine to weave for strength in certain areas and breathability in others,” Powick said. “The fabric allows more comfort for a newer climber.”

Pebax. BD developed three lasts (an anatomical representation of a foot that a shoe is built from)—neutral, moderate and aggressive for various types of climbing—each using pebax in the midsole. Pebax is a resin used in making ski boots and midsole components of some high-end athletic and track shoes. In the case of BD’s rock shoes, Powick said, the thin layer of pebax bonds to both uppers and soles easily and, more important from a performance perspective, will enable the shoe to keep its shape more effectively over time.

They’ve changed the way rands, the sticky rubber capping a climbing shoe’s toe and heel, are made. Instead of cutting a shape out of a sheet of rubber like a cookie cutter to rolled-dough, they’re injecting rubber into 3D molds (the same way BD builds a headlamp body or a stopper). Powick said this creates less waste as well as better consistency from shoe to shoe. By injecting a mold, a rand can easily be designed to incorporate stress-relieving flex points or be built thicker or thinner in key areas without having to be trimmed or shaved. Powick also noted that they are toying with ways to incorporate many types of rubber in one mold. Imagine a shoe seamlessly using different rubber formulations in strategic areas of the sole–stiff and durable here, soft and super sticky there.

***

Of course, the true measure of any new piece of kit, no matter how eye-popping the specs or materials, is how it performs. We’ve had a few models with testers for weeks already and will post a detailed review here on the Co-op Journal late this summer.

Until then, here are more photos from the line:

The full Black Diamond climbing shoe line. The four on the left debut this fall, the others in early 2018. | Photo: Shannon Davis

The Momentum’s woven uppers are designed to provide comfort and breathability. | Photo: Shannon Davis

The (super cute) Kids’ Momentum. | Photo: Shannon Davis

The Aspect features a leather upper, knit tongue, asymmetrical lacing with integrated lace protection at the toe, and a lateral stabilizing rand to keep your foot from rolling. | Photo: Shannon Davis

The Focus features a moderate, slightly downturned last for vertical to gently overhanging terrain. It has a leather upper, knit tongue, and stabilizing rand. | Photo: Shannon Davis