We’ve all been there: soaked, not because of a torrential downpour, but because of the sauna-like qualities of a waterproof jacket. The North Face is seeking to do away with this age-old tale with FUTURELIGHT™, their latest waterproof, super-breathable fabric, which is making its debut in the outdoor industry at Winter Outdoor Retailer.

“For so many years we’ve been changing our behavior based on the products, rather than the product changing its behavior based on the places we’re going,” said Jason Israel, global creative director of performance for The North Face.

It was two years ago on an alpine climb when Andres Merin, a competitive ice climber for The North Face, said to Scott Mellin, global general manager of mountain sports for The North Face,“The [climb] would have been so much safer and more efficient if we didn’t have to take off our jackets.” Having to pause to change layers in exposed areas can put athletes at risk. That single statement launched the hunt for a new fabric that would seal out water and release body vapor more effectively than other waterproof and breathable fabrics, even in high-aerobic sports like alpine climbing.

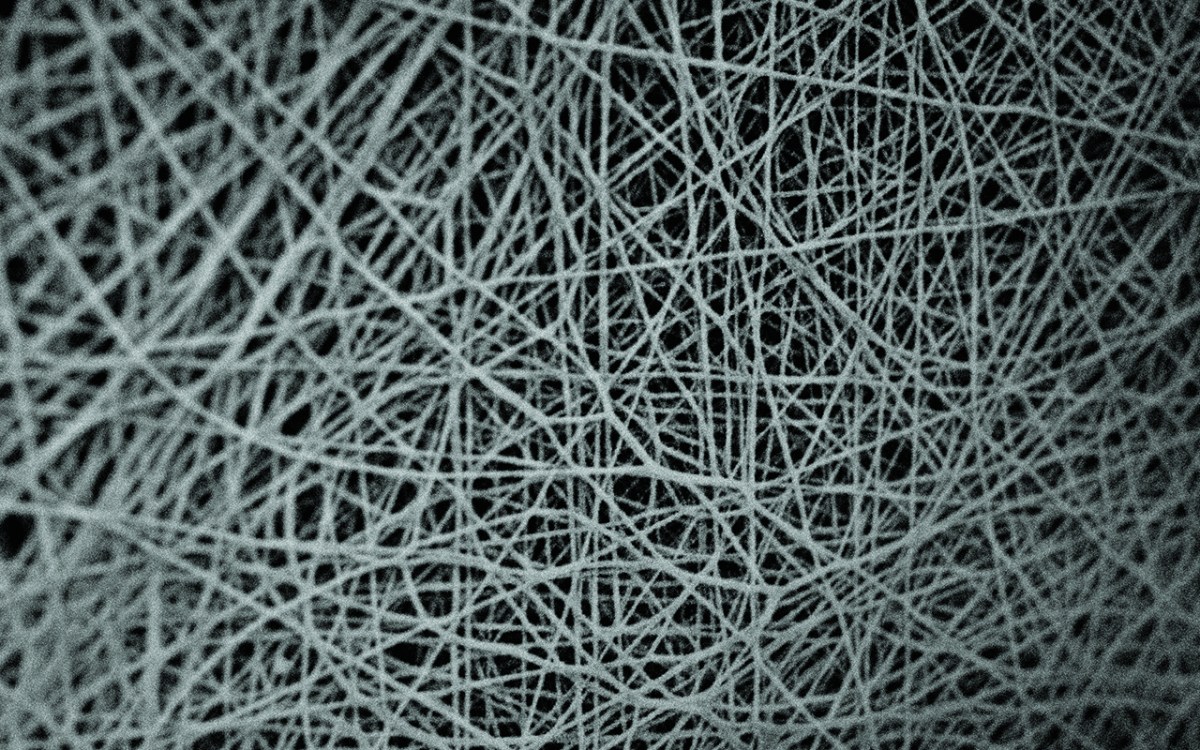

FUTURELIGHT is made using nanospinning technology, borrowed from the electronics and medical fields. Designers start with a polyurethane solution and extract that solution with 200,000 itty-bitty nozzles. When extracted, that liquid solution becomes 200,000 solid fibers which, when laid down on transfer paper, transform into mesh. “At the nanoscale,” Israel said, “there’s this really porous film structure—that’s the membrane. Under a microscope you can see the porous holes that don’t allow water in, but let it out.”

Nanospinning looks like this on the micro level.

This new membrane is not only super breathable, it’s also very lightweight. Whereas other membranes in the industry are, at their lightest, 20 grams per square meter, this membrane can be as light as three grams per square meter—which means designers have more freedom to create fabrics for everything from minimalist T-shirts to rough and rugged hard shells. All that technology results in a breathable, lighter, softer and quieter fabric. What’s more, it has the ability to stretch.

To tackle the research and development process, The North Face tapped it’s impressive array of professional athletes. Their product designers administered a blind test, sending each athlete unbranded apparel—some of it from The North Face, some of it not. Again and again, the brand received positive feedback on the breathability of its new fabric. “In all my years in the mountains, I’ve never experienced a product that moved and performed as well as FUTURELIGHT,” said Hilaree Nelson, captain of The North Face athlete team, in a press release. “It is creating a new paradigm for what I expect out of a waterproof material.”

Critical to the innovation process was making sure that the garments were produced in as low-impact a way as possible. FUTURELIGHT is manufactured in a solar-powered factory and is comprised of nearly 100 percent recycled fabrics. “It’s exciting to see a leading brand like The North Face bring a new technology to the outdoor industry that promises to elevate both performance and sustainability,” said Genna Heath, sustainable chemical program manager for REI.

But the innovation hasn’t stopped with outerwear. This fabric has wide-ranging applications, including the cover for the geodesic-dome frame for a BMW camper. “We wanted to demonstrate that the potential uses for FUTURELIGHT technology extend well beyond apparel,” said Ricardo Vengas, associate director of strategic partnering for Designworks, a BMW Group Company.

Designworks’ camper concept on display at The North Face FUTURELIGHT Experience: Las Vegas 2019.

FUTURELIGHT is already being crafted into The North Face’s fall 2019 product line, with a focus on snowsports.

Here at REI, staff members are ready to see it on shelves. “It’s exciting to see new materials innovation happening in the snow category, especially one claiming to be the most waterproof and breathable fabric ever created,” said Krista Hildebrand, senior category merchant manager for REI. “This technology will continue to push the limits on materials innovation … because a new standard has been set.”

Ready to see it in action? REI will be carrying a limited collection—consisting of snow-ready outerwear for both men and women—in October of 2019.